I first met Claude Delmas a couple of years ago when I gave a talk on African textiles at the Oriental Rug Society here in London and she had brought along several of the cloths she had woven. These turned out to be remarkable reproductions of some of the more unusual West African textile designs, including the intriguing Asante kente pattern known as “liar’s cloth.” The article we reproduce here with Claude’s kind permission was first published in 2008 in the Journal for Weavers Spinners and Dyers #227 . Having seen a loom set to weave “liar’s cloth” in the collection of the Deutsche Textilmuseum, Krefeld, I can confirm that Claude’s solution to the mystery of this design is the correct one.

“Nkontompo ntama – The Liar’s Cloth

Claude Delmas, London Guild

Looking at John Gillow’s book African Textiles my eye fell on the image of a lovely blue and white strip woven cloth from Ghana decorated with very precise inlay motifs. The caption read: ‘Liar’s Cloth in which blue warp threads are taken down the length of the cloth in stepped fashion’. The picture was so small that I needed a magnifying glass to see the blue stripes at all. There were three of them on one side of the strip which seemed to turn at right angles into the weft at regular intervals to continue on the opposite side. How could that be done?

The Research

Picton and Mack in African Textiles refer and defer to Venice Lamb’s exceptional field work in West African Weaving, and show in black and white a Liar’s Cloth from her collection – frustratingly indistinct for the non-expert. In her own book Lamb illustrates ‘an old Asante cloth with an inverted “liar” pattern. The liar pattern is fascinating: the warp thread is carried from side to side.’ In the small catalogue of the exhibition at the Halifax Museum of The Lamb Collection of West African Narrow Strip Weaving in 1973, there is yet another Liar’s in black and white. Hardly enough visual information to attempt such a feat on the loom! Nor were descriptions precise enough to help: Venice Lamb writes: ‘…there are a few devices which are rather harder to classify, such as the ‘floating warp’ technique used by Ashanti weavers to produce what they know as ‘liar’s cloth’, a kind of Greek fret pattern executed by shifting a warp stripe from one edge of the web to the other at regular intervals.’ And Kate Kent: ‘Ashanti weavers formerly produced…a handsome fabric called “liar's cloth” (Nkontompo ntoma), in which narrow lines meandered the length of a plain weave strip – either white lines on an indigo blue ground, or blue on a white ground. Blocks of weft-patterned design were woven over this warp pattern at regular intervals.’

It was the ethnographer R.S.Rattray in 1927 who established the name of the cloth as Liar’s. He made an extensive study of West African strip weaves, and put together a large collection of swatches, now in the British Museum, of both silk and cotton fabrics. Rattray’s swatch number 95 is a blue silk with two yellow and 2 red warp stripes and swatch 106 shows their meander into the weft and back on the opposite side. He elucidated the names given to the cloths according to the order and colour of warp stripes and attempting a description of the symbolism behind those names. His entry reads, ‘Nkontompo ntama’ (the liar’s cloth). The King of Ashanti is said to have worn this pattern when holding court, to confute persons of doubtful veracity who came before him.’ In 1969, another researcher Kate P. Kent was told that the shifting blue lines represented the liar’s speech.

Intriguing as it is, the name ‘liar’s’ and its meaning has survived, and it was interesting to find on the internet a mention of a Yale University thesis quite unrelated to textiles entitled ‘The Liar’s Cloth: Producing Veracity in the Victorian Courtroom’. Ethnographers seem to have been more exercised by the symbolism of the names than by the technique, and by their historical relation to status in the rigid hierarchy of the old Ashanti empire, where some combinations of stripes and patterns were reserved for royalty and nobility, the main sponsors of the weavers.

Traditional Kente cloth

Nowadays, after an eclipse lamented by writers of the 70s and 80s, it seems that narrow strip weaving is alive and well, whether worn as a mark of African identity or purchased by tourists, and the professional weavers formally trained by ‘masters’ in their workshops now even include women – witness a video recording produced in 1998 by the Open University as material for its Art and its

Histories course. The narrow strip loom of Ghana is well documented. The bundle of its 25 metres long warp is tensioned on a drag weight, its double heddle and reed, suspended from a frame, both pairs of heddles worked by the weaver’s feet. One heddle, the asatia, is threaded for the warp-faced tabby weave, the other, the asanan, threaded six by six ends, making itpossible to weave a weft-faced fabric at will and partially or completely cover the strip with decorative inlay left to the creativity of the weaver. Although some liar’s lines are worked along strips completely clear of inlay, the cloth that intrigued me had many indigo motifs and presented me with a double learning challenge. In The Art of the Loom Ann Hecht has a diagram showing the way to thread a modern four shaft loom to work like the double heddle loom – ground weave on shafts one and two, and weft-face on three and four, giving the same flexibility.

It seemed to me that in order to meander from side to side, the blue warps needed to be weighted independently at the back of the warp beam. To interlace with the weft, they had to be caught in heddles and go through the reed. My Texsolv heddle’s eye was large enough to take a small flat stick (a drinks stirrer) with the warp end wrapped on it, which I could manipulate in and out, use as a shuttle to weave in as weft, and return as warp, through empty heddles reserved on the opposite side, then back to their weight at the back of the loom. Not easy, but possible. Yet decidedly not the Ashanti way! More research was needed.

Floating warps?

Venice Lamb mentions a ‘floating warp’ technique in connection with the liar’s cloth. A few pairs of supplementary warps anchored independently on the cloth beam and weighted at the back would lie idle in the shed, neither held in the heddles or the reed, until lifted by the shuttle to appear as intermittent decoration on the cloth. As the liar’s lines weave continuously, it seemed to me that heddles were indispensable and floating warp not the solution. Another description suggested that ‘To make the meander pattern supplementary warps of liar's cloth served at times as weft. These were probably passed between the dents of the beater and through the eyes of the plain weave heddles when the loom was strung. They were thus part of regular plain weave when in the position of warps. When a warp pair was to be turned and used as a weft, it was cut to the appropriate length and woven in. The cut end would then fall free of the beater, but remain in the heddle eye. When it was to be re-utilized as warp again, it was pinned to the surface of the cloth – then woven in. (Ashanti weavers are accustomed to pinning any broken warp back into position in this fashion. The process outlined above was suggested by a young Ashanti weaver)’.

Convincing as this was, it failed to work for me, because I still had to move the blue warps from one side to the other, and I was left at each turn with four cut ends to darn back into the cloth in the usual way.

A theoretical solution

Not until I discovered the extraordinary survey and descriptive catalogue by Brigitte Menzel, mentioned in other works but never actually quoted or translated, Textilien Aus Westafrika, did I begin to see the light. Her swatches, like Rattray’s, relate mainly to the arrangement of warp stripes, but unlike him she concentrates, instead of the naming of cloths, on the exact thread count for each colour stripe. The swatch for ncontompo ntama shows 3 pairs of warps on the left, and the description says they are turned into the weft at 20cm intervals then vertically back into the warp. But it was the drawing that explained all. The warps are weighted, but at the front of the heddles! The blue threads are therefore wound on to the warp beam with the rest. And it dawned on me that there has to be two sets, one at each side of the strip. One set only weaves at a time, while the other rests attached to the weight, threaded in the heddles, but free of the reed. After 20cm of plain weave, one pair after another is cut off, freed of the reed and woven as weft to the appropriate point on the web to meet its opposite partner, which is detached from the weight, pinned on the cloth to be woven in on that side for the next 20 cm.

Looking at the real textile

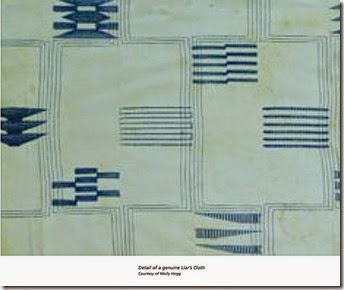

I was fortunate enough to be able to test this theory on a genuine liar’s cloth thanks to John Gillow and the generosity of his friend Molly Hogg, who owns an old and damaged but very beautiful one. Like all Ashanti cloths, its web is very dense warp faced, about 80 epi (a lot more than I had guessed) of fine machine spun cotton. The blue pairs are equally fine, and only show faintly on the cloth. The strips have been sewn together with exquisitely small stitches and the arrangement of the strips aligning the liar’s lines back to back – so to speak – create a fretwork into which the indigo motifs are slotted. It is impossible to know whether it ever had a traditional heading of densely brocaded designs at each end as it is coarsely hemmed instead. Nor can one tell if it ever had more than the present 21 strips. Very few of the inlay motifs repeat many times, some only occur once, and this somehow reveals the skill of its imaginative weaver.

With a magnifying glass, it is possible to ascertain that the threads are cut at the turn from weft to warp. Sometimes there is a small but discernible gap, and one can detect the closely cut thread ends. They are held by the density of the web, in the same way as the brocading wefts, without knots or darning in. Perhaps these cuts are the lie, the deception; The line doesn’t ‘turn back into the warp’, it is not continuous. Instead it is replaced by a partner.

Detail of Claude’s completed liar’s cloth.

The practical solution

To put this new understanding into practice, I warped up a long 4 inches wide strip with very fine white silk at 72 epi and dyed some silk in indigo for the supplementary weft. I included three pairs of indigo warp stripes on each side of the strip, entering them all in the heddles normally. However only one set of blue stripes went through the reed, while the other was weighted down in front of the heddles. After 20cm I needed to go through the following steps to turn the liar’s lines:

1. wind on the weaving so there will be enough space in front of the heddles to manipulate the blue threads.

2. disengage the first blue pair from the weight, bring it up through the reed at the appropriate place and pin it on the woven cloth.

3. cut the opposite blue pair long enough to become weft . Disengage the cut end from the reed and weight it in front of the heddles with a second weight.

4. weave the two cut warps into the weft one after the other to meet the pinned threads Then weave with the ground weft until the next blue pair needs turning into weft and repeat steps 2 – 4.

Two weights are needed until all three pairs have changed sides. After weaving half an inch or an inch, remove all three pins and cut all loose threads lying on the surface of the weaving closely. Because the sett of the cloth is very high, the cut ends stay caught in the web. For the next 20cm one can concentrate on working the inlays patterns, before returning the liar’s lines to the opposite side once again.

It seems easy, so it is likely to be right. Another interpretation of the name Liar’s cloth is that anyone who says they can weave it is a liar: I am hoping I have disproved that saying.

No comments:

Post a Comment