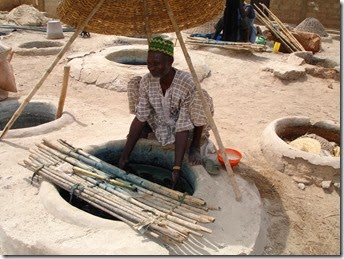

The famous indigo dye pits at the Kofar Mata gate in Kano may be the last few survivors in the city of what was once a massive local industry supplying highly prized burnished indigo turbans and robes to wealthy patrons throughout the Sahara and Sahel but today they are a rather sad sight, with only a few remaining dyers who largely make tie dye patterned cloths for the extremely desultory tourist trade. However a short drive outside Kano the village of Kura still retains its ancient specialisation supplying merchants from Niger and Mali. For the most expensive cloths cloth is woven from very fine spun cotton into strips only around 1 cm in width – these are the narrowest strips produced anywhere in West Africa.

Between sixty and one hundred and twenty strips are then sewn together edge to edge to make a turban before being dyed in indigo. In order to obtain the darkest possible colour the cloth is immersed and then drawn out to oxidise the dye repeatedly.

The dyed cloth is then dried in the sun.

It is then ready for the cloth beaters, another specialised craft requiring great skill.

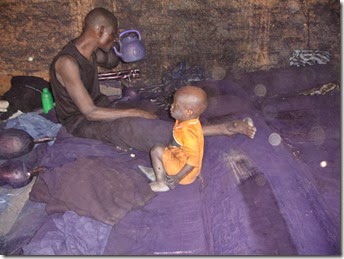

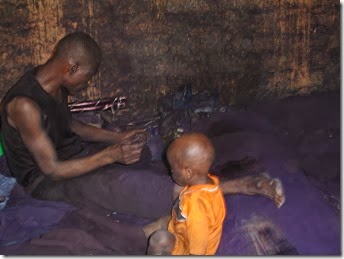

Water is sprayed onto a cloth dusted with powdered indigo and animal fat.

Two workers use heavy wooden mallets to beat the cloth, giving it a metallic sheen and folding it repeatedly until a long narrow bar of cloth is ready to be wrapped in paper for sale.

Two completed bars of cloth can be seen behind the seated man below.

Click on the photos to enlarge. All photos above © Duncan Clarke.

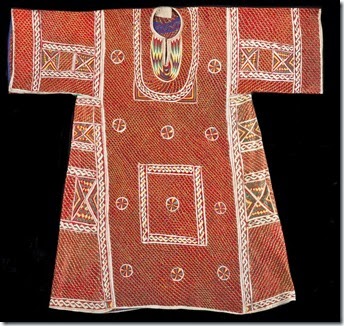

The Hausa/Fulani chief Sarkin Zamfara Ahmadu Barmo, Anka, north Nigeria 1961/62, photographer Brigitte Menzel. Indigo dyed and glazed turban.